SJTU SCCE Wang Jiulin Team Advance In Lithium-Sulfur Battery Research

November 23, 2018 Author: Yang Huijun

The Wang Jiulin Research Team of Shanghai Jiao Tong University began researching high-safety lithium-sulfur batteries in 2007. The S@pPAN sulfur composite cathode material created by the team has intrinsic non-combustible advantages (thermal cracking PAN is solid flame retardant) and uses various flame retardants. The additive eliminates the risk of burning organic solvents (Angew. Chem. Int. Ed. 2014, 53, 10099; Chem. Commun., 2014, 50, 7011; J Power Sources 2013, 223, 18). To ensure the safety of the lithium-sulfur battery during the full cycle of charge and discharge, the Team further used flame retardants as electrolyte solvent components (Chem Commun, 2018, 54, 4132).

Related work has been published online in the Angew. Chem. Int. Ed, with graduate student Yang Huijun as the first author and Wang Jiulin as the corresponding author. The work was funded by the National Natural Science Foundation of China (21333007, U1705255).

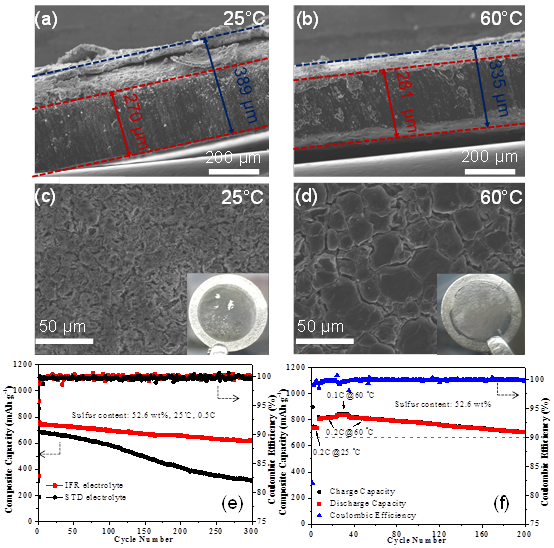

Abstract: Safety concern poses a significant challenge for the large- scale employment of lithium-sulfur batteries. Extreme flammable conventional electrolyte and dendritic lithium deposition cause severe safety issues. Herein, we report an intrinsic flame-retardant (IFR) electrolyte consisting of 1.1 M lithium bis(fluorosulfonyl)imide in a solvent mixture of flame-retardant triethyl phosphate and high flash point solvent 1,1,2,2-tetrafluoroethyl 2,2,3,3-tetrafluoropropyl (1:3, v/v) for safe lithium-sulfur (Li-S) batteries. This electrolyte exhibits favorable flame-retardant property and high reversibility of lithium metal anode (Coulombic efficiency >99%). Importantly, this IFR electrolyte enables stable lithium plating/stripping behavior with micro-sized and dense-packing lithium deposition at high temperatures. When coupled with sulfurized pyrolyzed poly(acrylonitrile) cathode (sulfur content: 52.6 wt%), Li-S batteries deliver high composite capacity (840.1 mAh g-1) and high sulfur utilization of 95.6%. More advantages of this system are its enhanced energy conversion efficiency and energy density under high temperature operation.

Read the article: https://onlinelibrary.wiley.com/doi/pdf/10.1002/anie.201811291

Translated by Iga Kowalewska Reviewed by Wang Bingyu